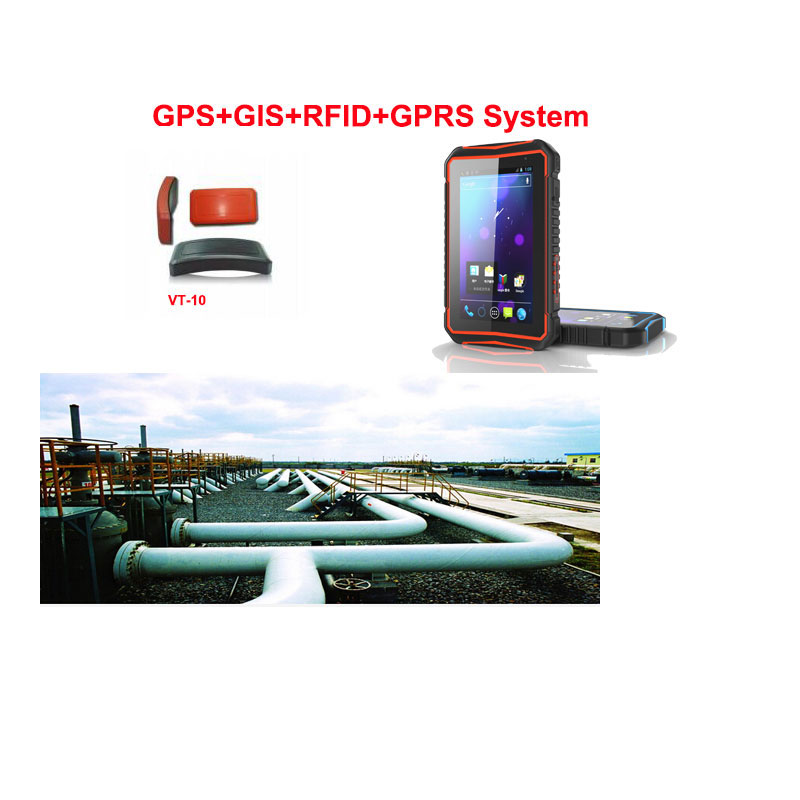

- Oil pipeline inspection with RFID PDA

- Describe

The difficulty in the field of oil pipeline transportation is the routine maintenance work of oil pipeline. Oil pipeline inspection refers to the equipment security department inspects and inspects the equipment and pipelines regularly to ensure the safety of oil transportation. Long-term work has been used in the inspection, "a table system" of work. Inspection personnel in accordance with inspection routes and inspection equipment and pipeline, and then select the operation on the table, return to the management of statistical inspection situation. As the inspection staff is not strong sense of responsibility, the weather conditions and other factors, and sometimes patrol officers lazy, false report inspection situation, making the quality of work safety inspection greatly reduced.

In the past, traditional maintenance management methods and models have been difficult to adapt to the requirements of modern operation and management, and the requirements of management informationization and standardization are becoming higher and higher. Especially, the development of geographic information technology GIS provides technical means and guarantee for oil pipeline management informationization . At the same time, PDA handheld devices for the terminal, the global positioning system GPS and GIS directly with the program has been in the work of oil patrol line in the rapid promotion of the traditional mode of operation to bring a new technological innovation.

The equipment / pipeline inspection system based on RFID technology mainly includes inspection and delivery management, inspection line management, inspection information download management, inspection information upload management, inspection information query management, inspection information report management and so on. Hardware devices are mainly composed of RFID handheld terminals and RFID tags, wireless access points. In the design of this system, closely around the industry's core needs and inspection operations of key business processes, and closely integrated RFID technology in the practical needs of the applicability, such as the choice of electronic tags using ultra-high frequency passive electronic Tag, the corresponding reading distance should be larger, so as to accurately detect the electronic tag information.

System working mode:

1. Initialization: First of all to establish a basic inspection line system database, can be obtained from the line management system. In order to achieve intelligence, but also need to collect all the coordinates of the geographical location of equipment. This process requires the patrolman to hold the terminal to go to each device, query the current equipment information, GPS module will automatically obtain the coordinates of the current location. And can be taken directly through the terminal equipment picture, as the information three-dimensional performance. Terminal has the RFID function can be verified with the background equipment, more convenient and accurate detailed understanding of the entire oil pipeline pipeline overall information, and reflected in the map information. The entire initialization process is simple, just patrolmen from start to finish inspection again, the system will get all the equipment GPS location data, device details and image information.

2. Daily inspections: each line of work before the inspection line will be the first to convey the inspection work orders. When the mobile explosion-proof Tablet PC to reach the required inspection sites, as long as the open machine, intelligent patrol system client program automatically through the GPS module to obtain the current location coordinates, and then local or in-house database of information, The device file is displayed on the terminal screen. Patrol line personnel to the situation in the field line equipment recorded in the handheld computer. At the same time, the system automatically activate the GPRS wireless network, the location information and the current time, together with the scene line with the record to the database, by the background inspection service program into the system database. If a GIS system is used together, PDA can display the electronic map, and navigation, guiding inspection routes.

3. Asset Inventory: the system can be sent to the inspection staff inventory check, while the completion of the inventory of assets inventory tasks, intelligent devices automatically complete the equipment inventory, inventory and inventory issued by the system, the first time to grasp the inventory situation, and The data sent to the system through GPRS, automatically generate disk loss to win statements.

4. Strengthen management: managers can pre-set the task list, arrange the daily inspection tasks, order, workload, routes and so on. When the patrol officers work, the system automatically according to the task list or scheduled to prompt the next line patrol inspectors. At the same time, the control center can monitor the progress of the patrolmen and inspect the situation at any time. Under special circumstances, managers can be uninterrupted through the wireless network scheduling command. Mobile terminals and back-end systems to maintain real-time data between the database to ensure that enterprise management information, to ensure that the inspection rate in place.

5. In order to ensure availability, the system supports online and offline work in two ways. If the GPRS wireless network because of signal problems temporarily unable to access, the system will be temporarily stored in the local data. Once the wireless network is available, the data is automatically sent. In addition, the system also provides a backup USB / infrared data set for transmission in a timely manner. When the wireless network is not used for any reason, the patrolman can synchronize the terminal in front of the USB / IR access device of the intelligent patrol service system.

The inspection equipment system full use of the RFID technology, the physical advantage, the main use of the UHF RFID without contact, read the characteristics of distance, without manual intervention, thus improving the inspection staff patrol convenience, greatly reducing the Inspection staff workload. RFID technology can be appropriate to improve the efficiency of inspection equipment to improve the management level; RFID technology can be suitable for long-distance data acquisition, better remote inspection equipment; RFID identification speed, reducing a lot of inspection time, improve efficiency, Through the cloth, leather, wood that material to read, and can fully respond to the challenges of harsh environments, to maintain all-weather work.

What is important is that RFID technology brings real-time and accurate data, enabling managers to gain insight into data and translating that insight into a best practice for business management, improving management and forecasting capabilities, and promoting holistic Efficiency and management.